Blog

Professional Irrigation Valve Boxes: How to Install Them?

13 November 2025

Valve boxes for underground irrigation systems are an integral part of the setup: they are containers that cover and protect components such as pipes, solenoid valves, and hydraulic connections.

In this guide, we’ll cover:

- The types of irrigation valve boxes in terms of materials, capacity, and durability

- The valve box installation process

- A comparison of the best-selling irrigation valve boxes in our catalogue

Types of Valve Boxes for Irrigation Systems

There are various types of irrigation valve boxes: the choice depends on the specific needs of the system and the conditions of the installation site.

Valve boxes are mainly distinguished by size, material, structure, and function. This classification helps identify the most suitable solution in terms of durability, ease of maintenance, and long-term performance.

Choosing the right valve box is not just a technical matter – it’s an investment in the overall performance of the system.

Sizes of Irrigation Valve Boxes

Valve boxes in irrigation systems fall into three main categories:

- Small (round): Circular in shape, ideal for housing a single solenoid valve or small fittings in tight spaces. Commonly used in residential gardens or small flower beds, where maintaining visual order and cleanliness is important.

- Medium (rectangular 20×30–30×40 cm): Suitable for 2–3 solenoid valves, commonly found in medium-sized gardens. They offer a good balance between capacity and ease of installation.

- Large (rectangular 40×60 cm or larger): Designed for manifolds with multiple valves (up to 6–8), typically used in professional or public installations where frequent access and operational space are essential.

Choosing the right size prevents overloads, facilitates technical interventions, and ensures a safer and more orderly water flow.

Materials of Irrigation Valve Boxes

One of the most important decisions concerns the material, which can determine the box’s longevity and resistance to external agents.

- Plastic (polypropylene or HDPE): Lightweight, weather-resistant and UV-stable, these are the most commonly used in both residential and professional settings.

- Concrete: Extremely robust, used in agricultural or industrial contexts where high mechanical protection and stability are required.

- Reinforced composites: More expensive but offer maximum resistance to foot traffic, impacts, and weather conditions – ideal for drive-over areas.

The material also affects daily usability: handling, inspectability, and stability vary significantly from one model to another.

Structure of Irrigation Valve Boxes

Beyond material and size, the structure determines the box’s practicality and its impact on the surrounding environment.

- Green flush-mounted lid: Discreet and ideal for gardens and domestic green areas.

- Drive-over: Reinforced to support vehicle traffic, essential when the box is located in transit zones.

- Telescopic: Height-adjustable to adapt to ground level variations and facilitate maintenance.

A well-designed structure contributes not only to the system’s longevity but also to the safety and aesthetics of the space in which it is installed.

Functions of Irrigation Valve Boxes

Function is what truly defines the usefulness of a valve box within the system. Each model is designed to meet a specific need and simplify the management of technical components.

- For solenoid valves: House valves, manifolds, and hydraulic fittings, essential for keeping the most vulnerable parts of the system accessible.

- For hydrants: Equipped with quick-connect fittings for manual hoses, ideal for public spaces or agricultural areas where flexibility is needed.

- For sensors and instrumentation: Contain moisture probes, meters, and filters, enabling automated and intelligent water management.

Understanding the function of each valve box allows for selection not only based on technical aspects but also on long-term operational efficiency.

This overview helps select the most suitable valve box based on available space, expected load, and the specific function of the system, ensuring maximum efficiency and longevity.

How to Install an Irrigation Valve Box

1. Preparing the Valve Box Area in the Irrigation System

Before starting installation work, it’s essential to properly prepare the intervention area to ensure long-term stability and durability.

Assessing the Ground

- Identify any areas with shallow water tables or standing water, which could compromise the box’s stability.

- Ensure the ground does not contain cavities or underground cracks to prevent subsidence.

Checking Capacity and Load

- Estimate the maximum load (pedestrian or vehicular) expected on the installation area.

- Check the system’s water flow rate to correctly size the valve box.

2. Excavation and Base Preparation for the Irrigation Valve Box

Excavation Dimensions

Dig with safety margins: at least 20 cm wider and 10 cm deeper than the box dimensions.

Creating the Bedding Layer

- Lay a 5 cm layer of coarse gravel or crushed stone to ensure drainage and stabilise the surface.

- Compact the base using a leveller or tamper until a perfectly level surface is achieved.

3. Sealing and Anti-Infiltration Protection for the Irrigation Valve Box

Waterproofing is essential to prevent water and soil infiltration.

- Apply a two-component epoxy resin along the entire inner edge to create a continuous waterproof membrane.

- Insert EPDM rubber gaskets at pipe and solenoid valve entry points.

- If the ground is unstable or subject to seasonal movement, place an expansion chamber at the base of the box to absorb any mechanical stress.

4. Positioning, Levelling and Connecting the Valve Box to Irrigation Pipes

After preparing the bedding and preliminary sealing, proceed with final installation.

Positioning and Levelling

- Place the valve box on the gravel bed, checking horizontal alignment on both axes with a spirit level.

- Check vertical alignment using a plumb line or weighted string.

Connecting to Pipes

- Cut the supply pipes with a fine-toothed saw to achieve clean, burr-free cuts.

- Insert sealing sleeves and EPDM gaskets, lightly lubricating with silicone grease to ease assembly.

- Secure fittings with stainless steel clamps or collars, ensuring even pressure around the circumference.

5. Assembly and Testing of the Valve Box in Irrigation Systems

The final step involves installing accessories and functionally testing the system.

Installing Accessories in the Valve Box

- Install a check valve to prevent unwanted backflow.

- Fit self-cleaning filters, essential for protecting solenoid valves from sand and debris.

- Position the electrical box or cable holder, connecting wires and conduits according to safety standards (IP65 or higher).

Functional Testing of the Irrigation Valve Box

- Start the system at design flow rate and maintain pressure for at least 10 minutes.

- Check for visible leaks along all joints and the inspection area.

- Measure solenoid valve opening/closing times with a stopwatch, ensuring they meet manufacturer specifications.

- Document test results in a report, including any corrective actions before handover to the client.

With these detailed steps, installing an irrigation valve box will ensure maximum efficiency, durability, and compliance with industry standards.

Our Best-Selling Irrigation Valve Boxes: A Comparison

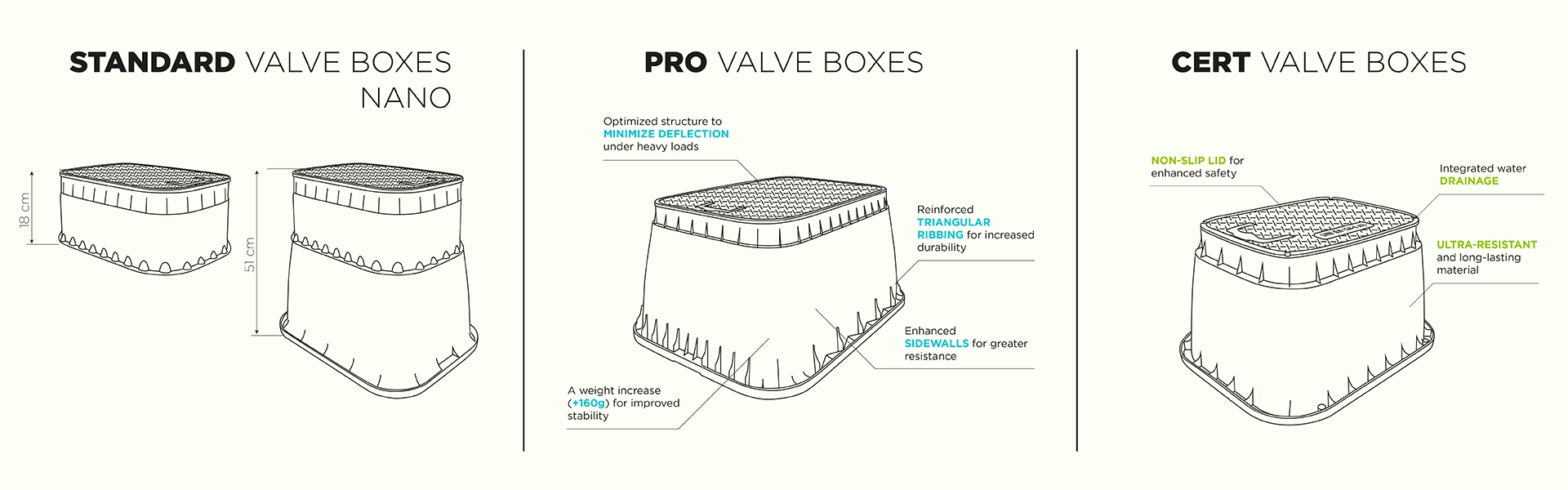

Our catalogue offers a range of solutions to meet every professional need, including Standard Valve Boxes, Pro Valve Boxes, and Certified Valve Boxes.

Standard Valve Boxes, such as the PZCR 15 model, are made of durable plastic and offer an affordable solution suitable for small to medium-sized residential systems with low pressure.

PRO Valve Boxes, like the EZ-OPEN PZRM PRO 117, provide greater rigidity and withstand high pressure, making them ideal for professional use in sports fields and commercial areas.

Certified Valve Boxes, such as the EZ-OPEN PZRM CERT 117, comply with EN and UNI standards and are specifically designed for public green spaces requiring high safety and durability standards.

Looking to optimise your irrigation systems?

After discovering the features of our irrigation valve boxes and the key steps to install them, it’s time to turn theory into practice.

Choose the solution best suited to your project needs – whether residential or public areas – and ensure long-lasting results that meet industry standards.

Contact us today: our specialised technicians are ready to support you before your purchase!

Discover the latest innovations

in irrigation systems!